DIN Rail Roll Forming Machine Bracket Cabinet Steel C U Channel | PUTAI

✅ High-Speed Production: Automated, continuous operation dramatically increases your output and reduces manufacturing costs.

✅ Integrated Punching: Option to include precise, synchronized punching for standardized mounting holes in a single pass.

✅ Built for Industry 4.0: Seamlessly integrates into automated production lines for smart manufacturing.

Product details

Key Advantages & Features

Uncompromising Accuracy: Produces rails with consistent, tight-tolerance profiles guaranteed to meet international standards, ensuring perfect compatibility with all electrical components.

High-Speed Production: Dramatically increases output compared to traditional methods, ideal for meeting large-volume orders and just-in-time manufacturing demands.

Superior Material Strength: The cold-forming process work-hardens the metal, resulting in a stronger, more durable final product than extruded alternatives.

Flexible Customization: Easily adaptable for different rail types (Top Hat, G, C-section), lengths, materials, and hole patterns through quick tooling changes and PLC programming.

Reduced Operational Costs: Automation minimizes labor requirements and material waste, maximizing overall cost-efficiency.

Product parameter

|

Product name |

DIN Rail Forming Machine |

|

Roller material |

Cr12 |

|

After-sales Service Provided |

Engineers |

|

Machine Type |

Casting frame steel structure |

|

Shaft material |

40Cr Steel Forging Treatment |

|

Place of Origin |

TIANJIN |

|

Minimum order quantity |

1 set |

Product advantages

Product display

Uncoiler: A decoiler feeds the raw metal coil into a precision leveling system, which eliminates any internal stresses and curvature, ensuring the strip is perfectly flat before forming.

Punching (Optional): For perforated rails, a servo-driven punching unit operates in perfect sync with the moving strip, accurately punching mounting holes at programmed intervals without stopping production.

Entry Beach: Put the raw material (steel plate) through the beach to manufacture and process

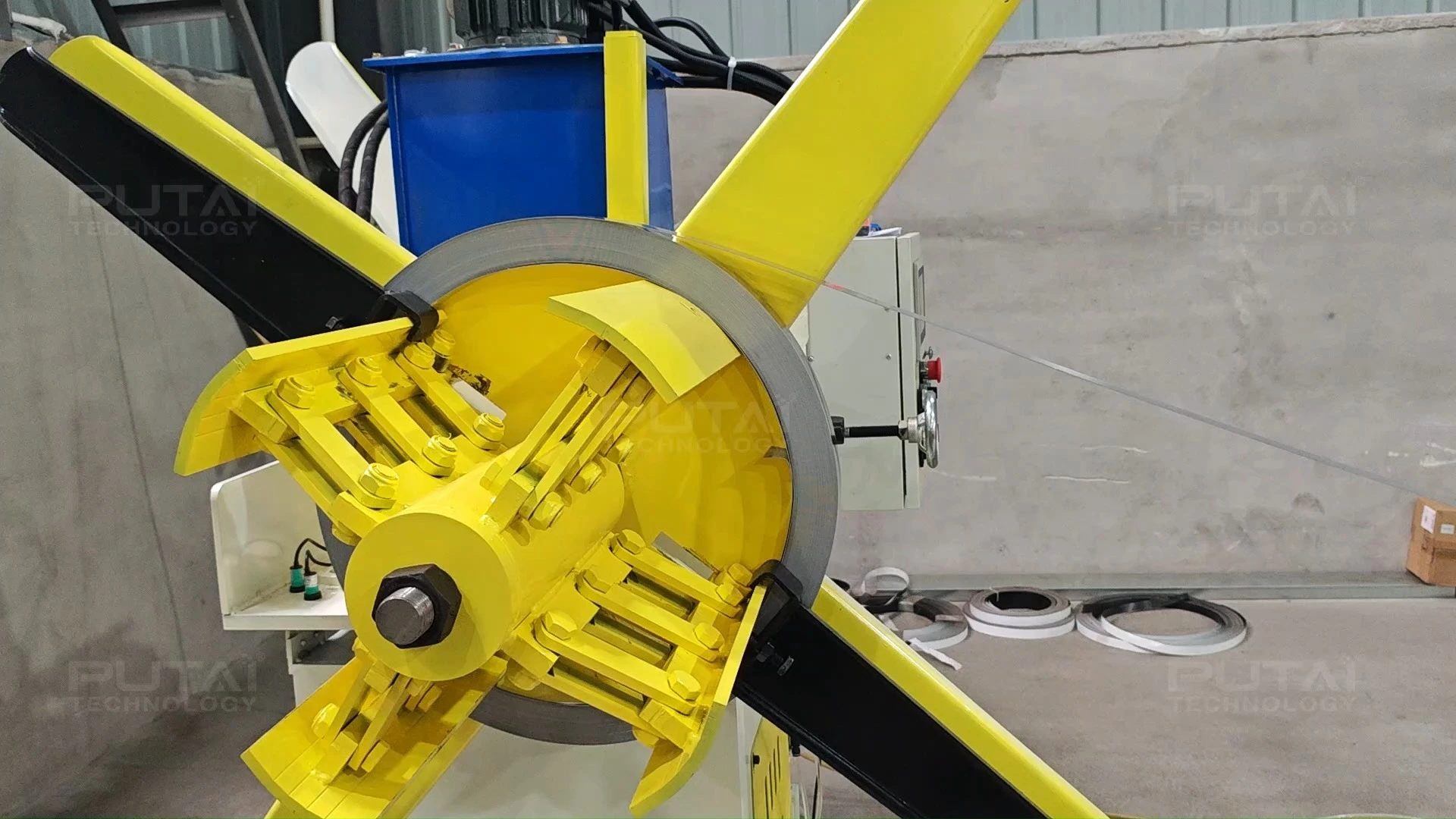

Progressive Roll Forming: The heart of the machine. The flat strip is guided through a series of contoured roller dies. Each station incrementally bends the metal until it achieves the exact final profile—be it the common TS35, TS32, or other standardized variants—all without material removal, preserving the metal's integrity.

Hydraulic Station: Oil cylinders and oil pumps adopt national standard rod oil cylinders, easy to purchase all over the world.

Servo system cutting: The servo motor drives the tracking system, which sets the product length by measuring the length with a counter or locating the product length with a photoelectric switch hole.

Collecting Product Table: Manual Simple collecting product table.

Company Introduction

Our company Bazhou chenglang factory and Putai company(Tianjin Branch) is a professional cold roll forming machine manufacturer,we have been focusing on this field for 23 years. Our equipment includes roof forming machine, floor deck machine, automatic hydraulic uncoiler machine, shutter door coiling machine, light keel cold roll forming machine,stud and track C Z U forming machine, whole equalizer machine and other related construction equipment. With more than 22 years of engineering and design research and develop team. We have two patents for independently developed machine .At the same time, our machines use brand electrical components, raw materials from brand steel mills, strict process control, two year warranty, installation and training services.

Company tenet

Our customers all over the world, such as Germany, the United States, Mexico, Chile, Bolivia, Italy, Australia, Kuwait, Saudi Arabia, South Korea, South Africa, Kenya and other countries and regions. We have rich experience in different country needs such as profiles, thickness ranges, use, installation etc.

Company tenet: technological innovation, customer - centered, win-win. Thank you for your trust and choice, we will provide you with the best service support, help you achieve greater success. We look forward to more cooperation with old and new friends from all over the world!

Our R & D team has won a number of patent certificates and quality outstanding brand awards

Packing&Shipping

Customer Praise

FAQ

Tianjin Putai Technology