Идеальный формовщик рулонов производства PUTAI.

Automatic Drywall Profile Roll Forming Machine High Speed Steel Furring Channel C U Omega | Putai

Product details

Project case

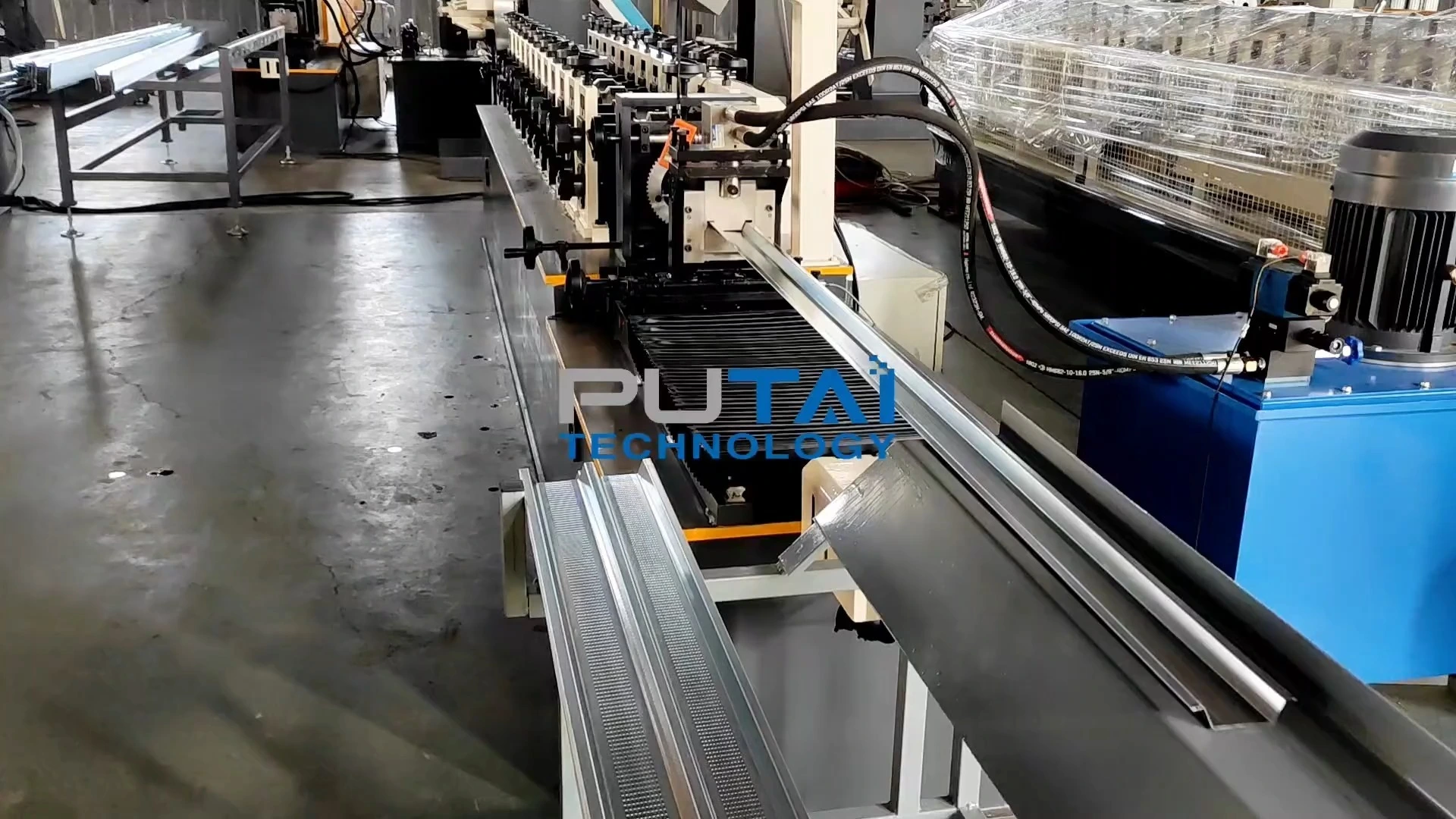

Putai Technology Factory's Hat Channel Roll Forming machine is ideal for producing metal profiles used in drywall partitions, ceilings, and other building structures. This versatile machine can produce various profiles such as studs, tracks, furring channels, and wall angles with high precision. El Drywall forming machine is equipped with robust cutting mechanisms, material feeding systems, and adjustable forming rollers for maximum flexibility. Our drywall profile roll forming machine is capable of producing profiles of different sizes and thicknesses, making it suitable for a wide range of construction projects.

Parámetro del producto

Product name | Hat Shape Forming Machine |

Roller material | Cr12 |

After-sales Service Provided | Engineers |

Machine Type | Drywall Forming Machine |

Shaft material | 45# Steel Forging Treatment |

Place of Origin | TIANJIN |

Minimum order quantity | 1 set |

Ventajas del producto

Exhibición de productos

Uncoiler: Put the steel coil on it for feeding raw material

Entry Beach: Put the raw material (steel plate) through the beach to manufacture and process

Main Roll Forming Machine: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear box transmission, roller surfaces polishing, hard plating, heat treatment

Hydraulic Station: Oil cylinders and oil pumps adopt national standard rod oil cylinders, easy to purchase all over the world.

Servo system cutting: The servo motor drives the tracking system, which sets the product length by measuring the length with a counter or locating the product length with a photoelectric switch hole.

Collecting Product Table : Manual Simple collecting product table

Company Introduction

Our company Bazhou chenglang factory and Putai company(Tianjin Branch) is a professional cold roll forming machine manufacturer,we have been focusing on this field for 23 years. Our equipment includes roof forming machine, floor deck machine, automatic hydraulic uncoiler machine, shutter door coiling machine, light keel cold roll forming machine,stud and track C Z U forming machine, whole equalizer machine and other related construction equipment. With more than 22 years of engineering and design research and develop team. We have two patents for independently developed machine .At the same time, our machines use brand electrical components, raw materials from brand steel mills, strict process control, two year warranty, installation and training services

Company tenet

Our customers all over the world, such as Germany, the United States, Mexico, Chile, Bolivia, Italy, Australia, Kuwait, Saudi Arabia, South Korea, South Africa, Kenya and other countries and regions. We have rich experience in different country needs such as profiles, thickness ranges, use, installation etc.

Company tenet: technological innovation, customer - centered, win-win. Thank you for your trust and choice, we will provide you with the best service support, help you achieve greater success. We look forward to more cooperation with old and new friends from all over the world!

Our R & D team has won a number of patent certificates and quality outstanding brand awards

Embalaje&Shipping

faq

Тяньцзинь Путай Технология