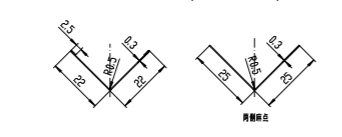

Project Description

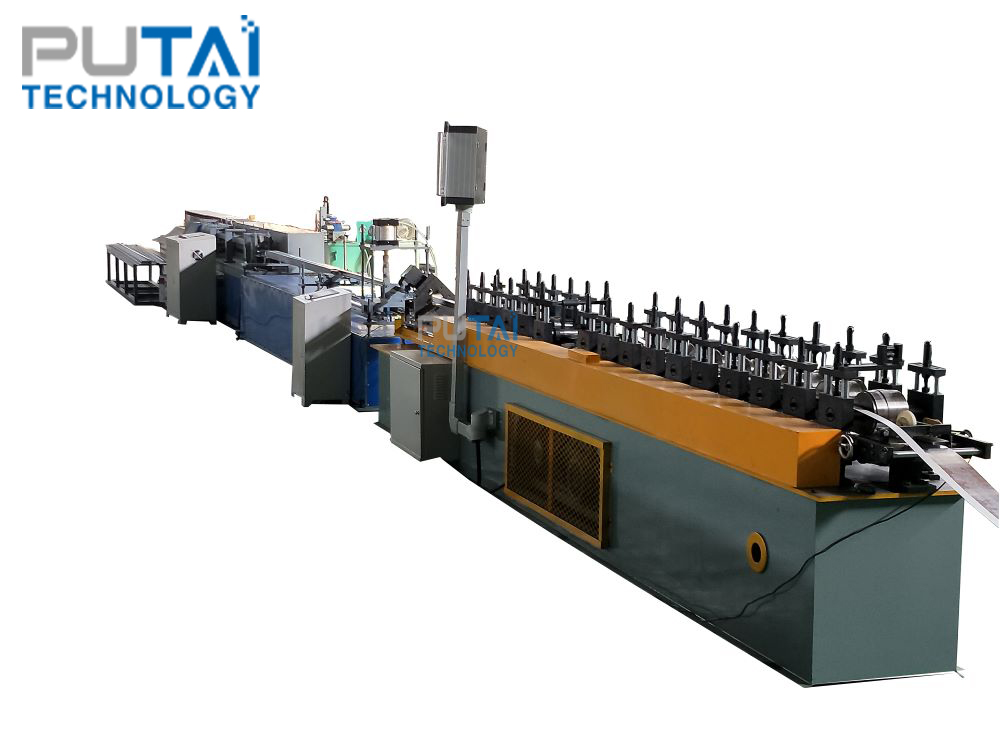

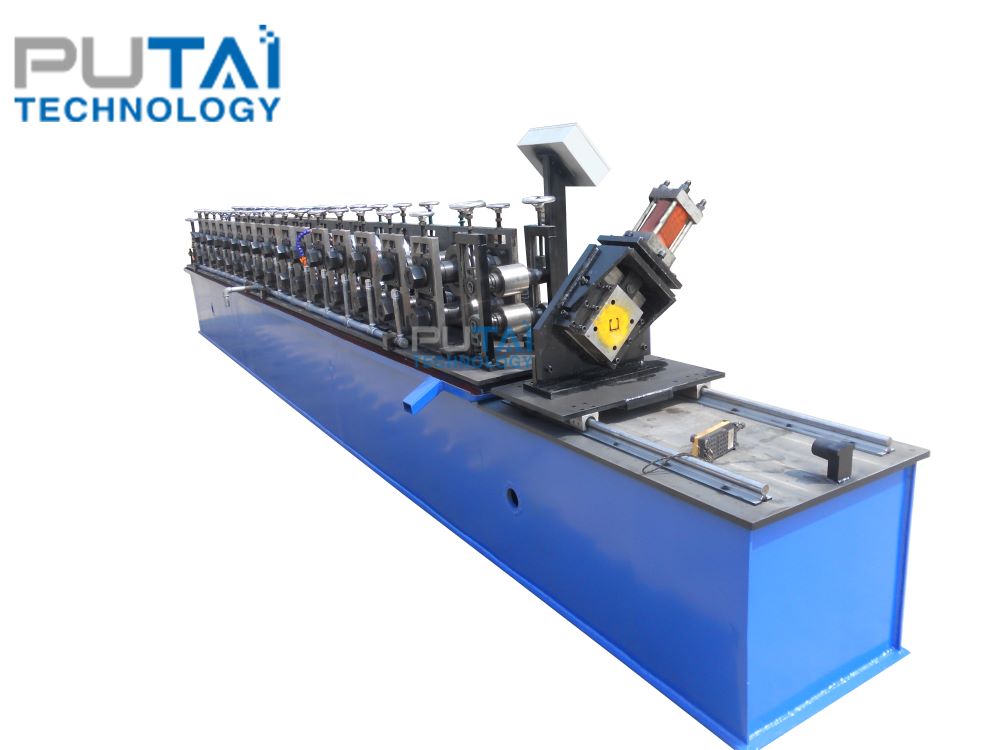

Omega Channel Forming Machine

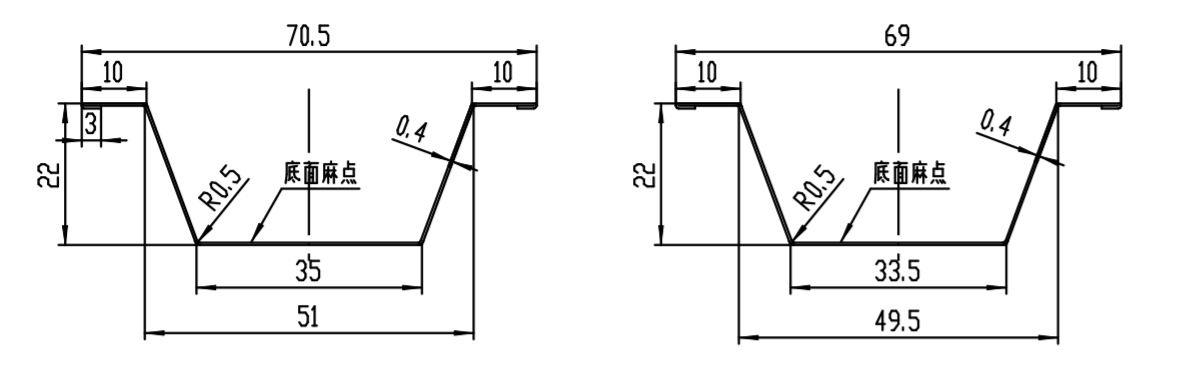

Specification for omega channel roll forming machinery |

||

|---|---|---|

Decoiler |

Weight | 150kg |

| Steel coil ID | 450-550(mm) | |

| Steel coil OD | 1500(mm) | |

Roll Forming Machine |

Rollers | 8-12Rows |

| Material: Cr12 | ||

| Inner diameter:40mm Outer diameter:90mm | ||

| Heat treatment hardness:HRC58-62 degree | ||

| Transmission | The transmission is chain and gear | |

| Middle Plate | Thickness is 25mm | |

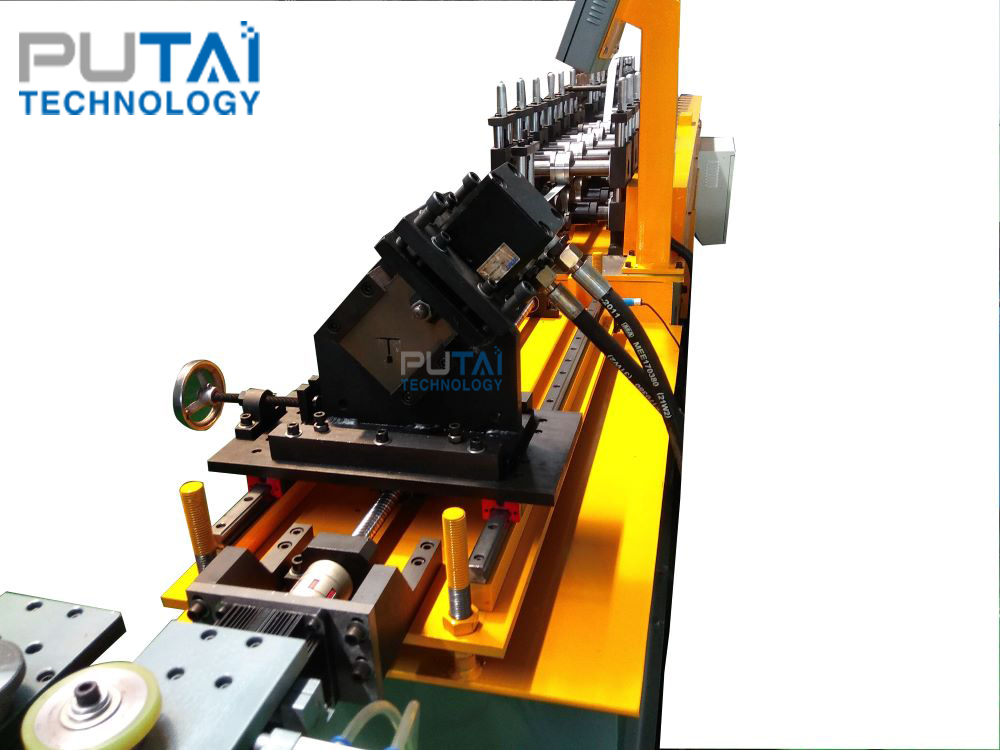

Hydraulic System |

Power | 4/5.5KW |

Cutting System |

Servo Tracking System | Yes |

Cutting Material |

Cr12 | |

Professional engineer is available to buyer’s factory

Make your omega channel forming machine run well, keep your business running well!

Advantages of omege channel forming machinery

Steel c u channel roll forming machine’s performance is stable.

Light keel roll forming machines are produced as Client’ requirement

We can make and design roll forming machine according to customer’s request.

High quality machine with good price.

Stud and track roll forming machine’s design is essy to adjust, becauseof reasonable structure, high precision and high efficiency.

Low labor cost and fully automation save your money from every part!

Professional team for research and development

Provide professional engineer to client’s factory

We make your machines run well, keep your business running well!

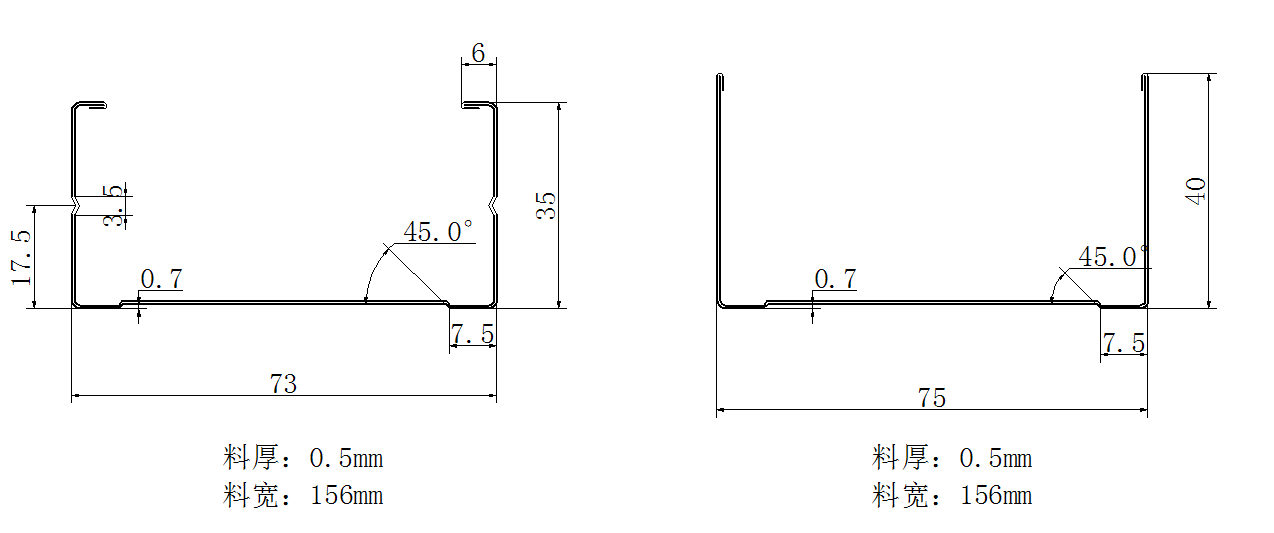

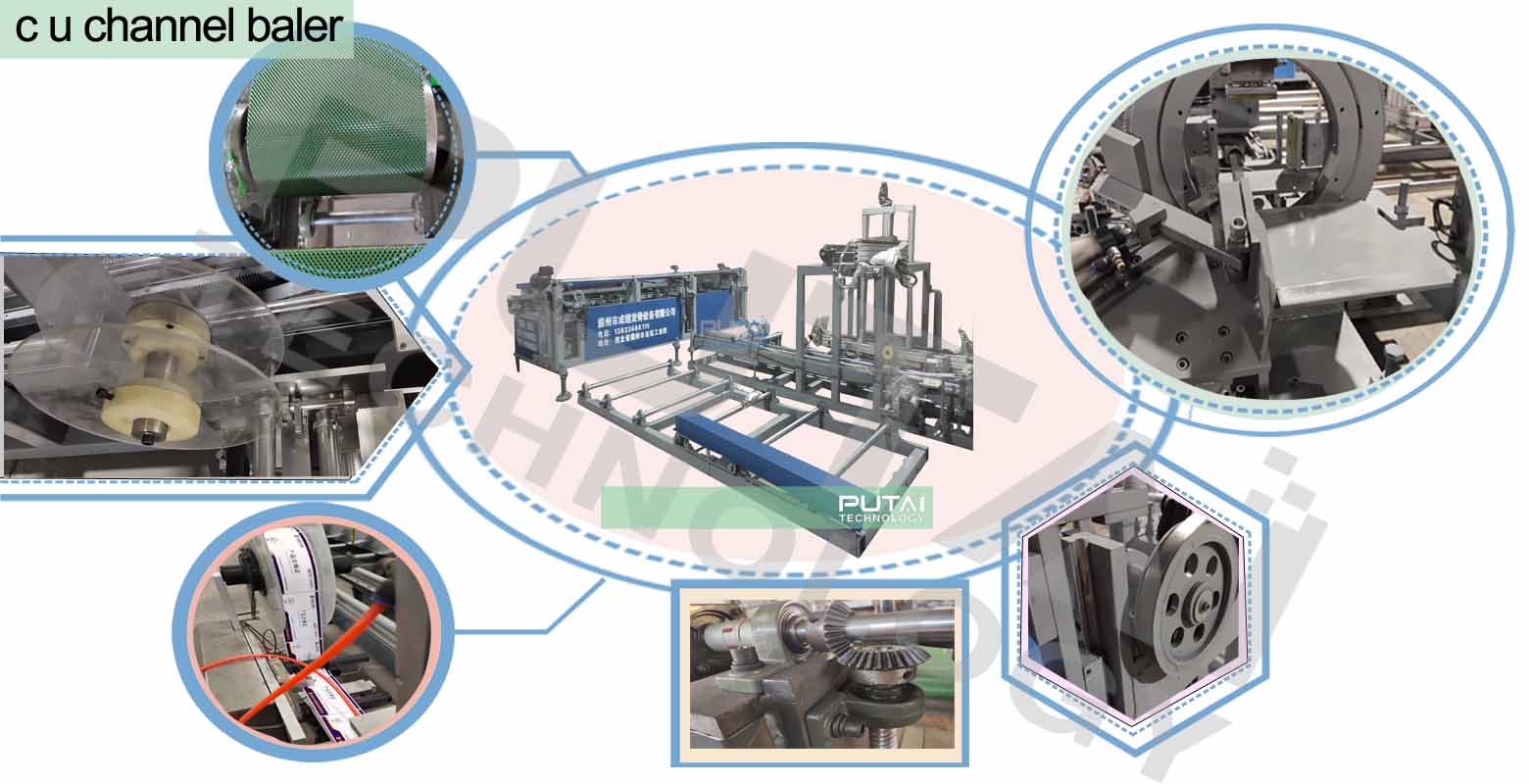

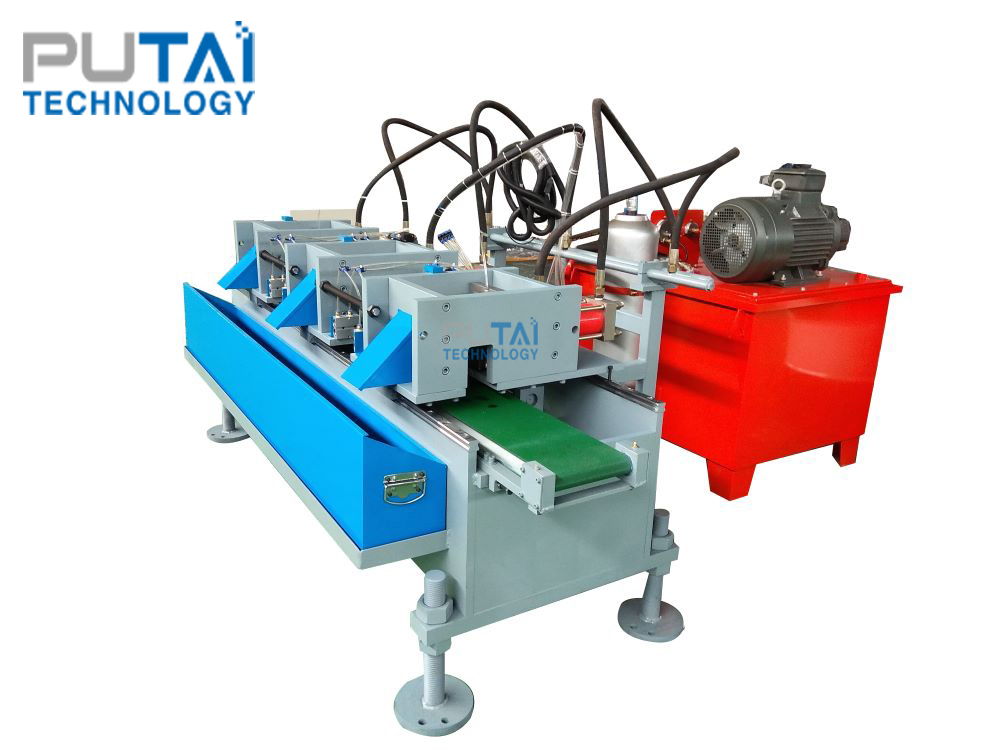

Specification for C U steel channel baler(package machine) |

||

|---|---|---|

Main machine body |

Frame | 80*80*3mm welded steel square pipe |

| Steel coil ID | 420-450mm | |

| Steel coil OD | 1000mm | |

| Conveyor | thickened non-slip conveyor belt | |

| Double hook material | Material: Cr12, heat treatment | |

| Transmission shaft | 45# steel, and surface chrome coating | |

| Screw | 2525 Ball screw | |

| Lift part | Brake motor is adopted to continue to work | |

| Push part | Servo motor; for better flexibility; chain drive | |

| Slide | Using 45# steel,heat treatment surface coating chrome | |

| Stuffing | TN cylinder is to prevent rotation | |

Marking |

positioning system | Manual adjustment, flexible operation, accurate positioning |

Advantages of steel c u channel baler

Steel c u channel baler performance is stable, no noise.

Save workers, save time, more efficient.

We can make in the shortest delivery time. we make this machine 1 set/day to reach market requirements.

High quality machine with best price.

The design of blaer machine is easy to adjust, for it owns reasonable structure, high precision and efficiency.

Low cost and ful-automation save your money from every part!

Professional team for technical research and development. So contact us freely.

Related Products

Ask for price and solutions today!

Your inquiry will be replied ASAP, we respect your privacy.

.jpg)